410 Nova

Guaranteed quality at your finger tips.

Perfect surfaces, practical and safe, ergonomics.

Discover the "Xylent" cutterhead, available for this machine.

Advantages

Precision that lasts a lifetime without noise with the system on connecting rods.

The system guarantees the maximum movement fluidity and avoids deformations of the work table. This guarantees maximum stability, reliability and ergonomics.

Total absence of vibration thanks to the large worktables made from ribbed cast-iron.

Exceptional finish with the “Xylent” spiral knife (3 spiral knives)

Reduced noise during machining provides a more comfortable working environment. It also improves the dust extraction due to the production of very small chips. Each cutter has 4 tips which can be rotated into the cutting position when worn. Therefore increasing the production life of the cutter block before knives require replacement.

Videos

SCM 410 Nova

Noise test on Xylent Cutterhead

Nova s 520 - Nova s 630

Guaranteed quality at your finger tips.

Easy and precise, practical design, a wider range of applications.

Discover the "Xylent" cutterhead, available for this machine.

Advantages

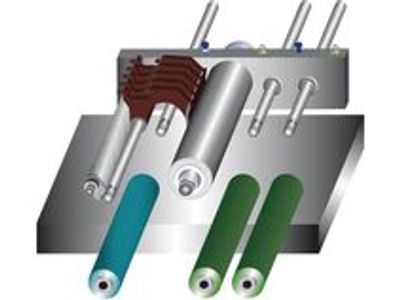

One machine for every requirement with the interchangeable rollers. Quik and easy changeover of the rollers that allows the operator to configure the machine drive function in case of special requirements such as minimum removal of fine wood and/or batches where multiple pieces of different thicknesses are processed.

Perfect finish with the feeding rollers on connecting roads. The stopping of the work piece and the presence of notches on its surface are eliminated due to the movement system on all three rollers that allows their vertical displacement by rotation and the best linear feeding.

Sturdy structure with precision when moving the work table

The 4 screws with a large diameter combined with the 2 side linear guides ensure worktable stability eliminating the necessity of locking in position. The integrated protections guarantee high precision and reliability over time.

Exceptional finish with the “Xylent” spiral knife (3 spiral knives) Reduced noise during machining provides a more comfortable working environment. It also improves the dust extraction due to the production of very small chips. Each cutter has 4 tips which can be rotated into the cutting position when worn. Therefore increasing the production life of the cutter block before knives require replacement.

Video

Noise test on Xylent Cutterhead

Class s 630

The best solution for every application.

Easy and precise, practical design, a wider range of applications.

Discover the "Xylent" cutterhead, available for this machine.

Advantages

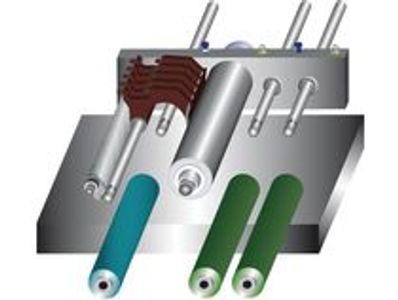

The best finish and effectiveness of the feeding of any material and in any working condition thanks to the pneumatic adjustment of rollers that allows to change at any time the pressure exerted on the work piece.

One machine for every requirement with the interchangeable rollers. Quick and easy changeover of the rollers that allows the operator to configure the machine drive function in case of special requirements such as minimum removal of fine wood and/or batches where multiple pieces of different thicknesses are processed.

Perfect finish with the feeding rollers on connecting roads. The stopping of the work piece and the presence of notches on its surface are eliminated due to the movement system on all three rollers that allows their vertical displacement by rotation and the best linear feeding.

Sturdy structure with precision when moving the work table

The 4 screws with a large diameter combined with the 2 side linear guides ensure worktable stability eliminating the necessity of locking in position. The integrated protections guarantee high precision and reliability over time.

Video

Nose test on Xylent Cutterhead

Legno Lab Albero

Contact Us

Call or text Ken Dobranski at 587-888-0181

or email ken@dobsales.com

Copyright © 2021 DOB Sales - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.