Startech cn Plus

startech cn plus has been designed for the small-medium woodworking workshops but also for larger companies that produce customized products, with in house prototype development departments. Thanks to the 8 independent vertical spindles, the 6 horizontal spindles, the blade in "X" . There is a machine version with router.

FLEXIBLE: IDEAL SOLUTION FOR TAILORED PRODUCTIONS

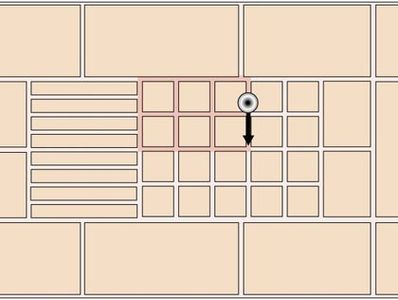

No operator's intervention for the worktable and machine set-up according to the panel dimensions.

PERFORMING: TOP PERFORMANCE

Tooling and machining operations reduced to the minimum, with 40 m/min axes speed.

COMPACT: VERY REDUCED MACHINE OVERALL DIMENSIONS

With its 5 m2 overall dimensions, it can be installed in reduced spaces.

SIMPLE: AT EVERYBODY'S REACH

Easy-to-use machine and for every investment capability

Site Content

Effective: The operating unit above the panel allows a very precise and cleaned working. Furthermore any panel thickness imperfection is hidden inside the furniture (part not in sight).

Maximum versatility: The machine version with routing unit with electrospindle 5.5 kW motor power is suitable for all machining.

Totally automatic: thanks to the automatic side alignment device the panel is loaded, into the machine and recovered at the end of the boring-milling program, without any other intervention required by the operator.

A "Maestro" at your disposal: 19" PC with integrated software. The SCM "Maestro cnc" software allows to create projects and geometrical drawings to be automatically converted in drilling-routing programs for the machine.

Contact Us

Call or text Ken Dobranski at 587-888-0818

or email ken@dobsales.com

Morbidelli N 100

Machining centre designed and engineered for woodworking.

Thanks to the unique design and PRO-SPACE safety systems directly integrated onto the machine, a reduced floor space is required and is accessible from all sides to place panels or small components on the work table.

Advantages

MINIMUM OVERALL DIMENSIONS AND MAXIMUM FLEXIBILITY: “PRO-SPACE” PROTECTIONS

Loading zone completely free to reduce the space occupied to the minimum. The absence of perimeter protections facilitates the work table access on all the sides of the machine.

THE PERFECT DRILLING:

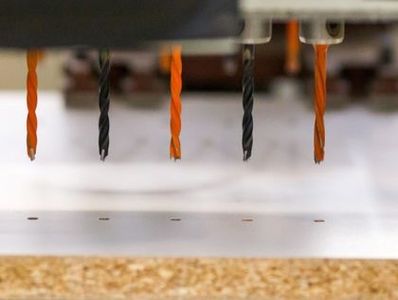

RO.AX SPINDLE

Zero play during machining with the new RO.AX technology (Rotoaxial spindle technology), the most efficient spindle on the market with rotation speeds up to 8000 rpm. The sturdiness of drilling heads is proven by the reduced maintenance costs: five times less than that imposed by the majority of other machine manufacturers.

DESIGNED FOR EFFICIENCY AND SAVING: “H.E.” (High Efficiency) WORK TABLE

Sturdy and practical work table, resistant over time thanks to its laminate aluminum structure.

Easy and quick setting with the magnetic locking system of the vacuum: in a few seconds the vacuum is activated only in the positioning area of the piece to be machined.

TOTAL ABSENCE OF VIBRATIONS:

MOBILE GANTRY STRUCTURE

Performance without comparison with the mobile gantry structure that allows for high machining speeds whilst guaranteeing the best end products quality.

Software

Contact Us

Call or text Ken Dobranski at 587-888-0818

or email ken@dobsales.com

Morbidelli 200X / 400X

Additional Information

The new generation of Nesting CNC machining centres meets the needs of a market increasingly oriented towards flexible and batch-1 production, combining excellent performance, maximum configurability with increased flexibility and productivity.

Every detail is designed to make any performance accessible, leading to efficiency, quality and business evolution.

Advantages

NOT ONLY NESTING:

FLEXIBLE

Any machining process without removing the spoilboard and even in 3D thanks to the X-PODs and the JQX (Just Quality eXtreme)

5-axis electrospindle.

FASTER THAN ANY OTHER MACHINE

Nesting processing at 50 m/min, saves 60% of time on drilling cycles thanks to the new drilling heads (also with double saw blade) and less than 15” for the tool change thanks to the FAST tool changer directly installed on the mobile unit.

MAXIMUM HOLDING:

TOP QUALITY

Thanks to the X-Vacuum System, the vacuum is condensed into the area of the worktable where the workpiece is being processed.

Perfect to process small workpieces or highly breathable materials.

HIGHLY MODULAR

The ultimate solution to simplify work: cell version, available to configure the machine no matter the material flow required.

Software

Downloads

Morbidelli 200 400X Technical Data (pdf)

DownloadContact Us

Call or text Ken Dobranski at 587-888-0818

or email ken@dobsales.com

Morbidelli CX210 / CX220

Additional Information

The best solution for batch-1 processes.

Compact and smart CNC drilling centres, perfect to grant drilling on 5 sides of the panel, grooving and routing operations. No manual inverventions on the machine between two operations allowing uninterrupted machining cycle.

Also available with automated panel return conveyor for a continuous cycle production.

Advantages

THE PERFECT DRILLING:

RO.AX SPINDLE

Zero play during machining with the new RO.AX technology (Rotoaxial spindle technology),

the most efficient spindle on the market with rotation speeds up to 8000 rpm. The sturdiness of drilling heads is proven by the reduced maintenance costs: five times less than that imposed by the majority of other machine manufacturers.

+70% OF PRODUCTIVITY:

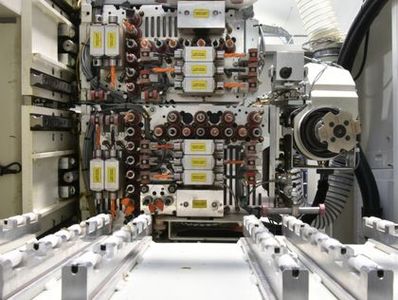

TWO DRILLING HEADS

morbidelli cx220 machining time is considerably reduced: two drilling heads with independent Y and Z axes, automatically program-managed, can machine on a panel at the same time

PERFECT SURFACES:

NEW WORK TABLE

No scratching thanks to the new properly designed work table,

the best solution for machining of lacquered and delicate panels.

CYCLE TIME OPTIMIZATION: SHAPED CLAMPS

Reduced cycle time and no repositioning: the new clamps' design allows drilling and routing operations even on the inside of the clamping area.

Software

Contact Us

Call or text Ken Dobranski at 587-888-0818

or email ken@dobsales.com

Copyright © 2021 DOB Sales - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.