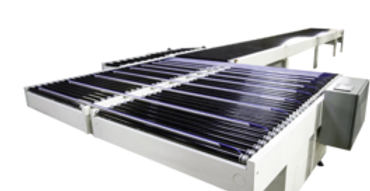

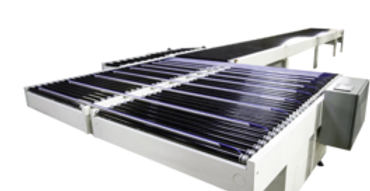

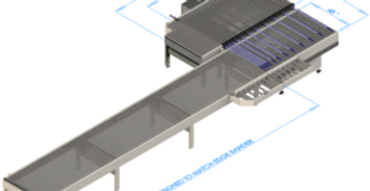

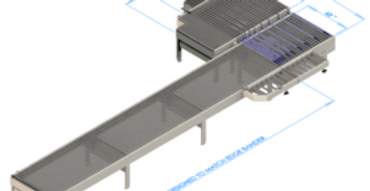

EDGE return conveyor

Additional Information

- SCM is pleased to introduce a standard ERC series conveyor to be paired with all edgebander models. The edgebander, coupled with an ERC return conveyor, streamlines workflow and creates an efficient and cost-effective solution to handling panels without the need for an additional operator. The result is labor savings, increased machine efficiency, reduced handling damage and less rejects. Independently adjustable speed control of the receiving table, transfer belts, and return conveyor allow the operator to customize settings for a perfectly balanced system regardless of the panel size. Additional options include the panel kicker, panel rotator, panel exit assist and panel support rollers.

Additional Options

Panel Kicker

Panel Rotator

Panel Rotator

Angles narrower panels, ensuring transfer belts engage the workpiece with the ability to adjust the operating parameters based on process needs in real-time.

Panel Rotator

Panel Rotator

Panel Rotator

Allows conveyor to accommodate longer panel lengths by Rotating panels to the next edge for banding, eliminating the need for manually rotating large panels.

Panel Exit Assist

Panel Support Rollers

Panel Support Rollers

Eliminates risk of a deadzone developing at the outfeed of the edgebander for especially small panels. Provides an increased reliability and repeatability of transfer from the edgebander to conveyor by positively engaging panels with a driven belt

Panel Support Rollers

Panel Support Rollers

Panel Support Rollers

Ideal for long, thin panels that have a tendency to deflect The support rollers allow returning panels to pass under panels being banded, when included with the panel rotator.

Advantages

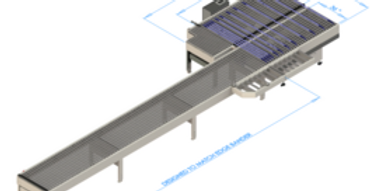

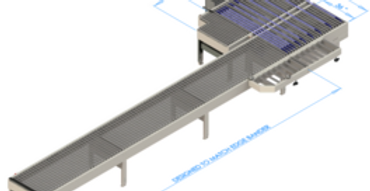

MACHINE MATE TRANSFER ROLLER SECTION

Allows for seamless interfacing with SCM edgebanders facilitating smooth transitions from edgebanding to conveying. Polymer coated steel rollers provide strength and stability while maintaining a non-marking surface for panel contact.

INTUITIVE TOUCHSCREEN

Allows for independent speed adjustment of the outfeed, transfer belts and return conveyor sections with a 7” operator panel and PLC on board for conveyor sequencing.

Panel Support Rollers

Panel Support Rollers

FABRICATED STEEL FRAME WITH BOLT DOWN FEET

Ensures a stable base for conveyance. Adjustable leg sets allow for flexibility when leveling conveyor.

Panel Support Rollers

Panel Support Rollers

Panel Support Rollers

MULTIPLE RECEIVING TABLE LENGTHS AND WIDTHS

Allows for a comprehensive range of panel sizes. Return conveyor lengths are tailored to the SCM edgebander model.

Media

Contact Us

Call or text Ken Dobranski at 587-888-0818

or email ken@dobsales.com

Copyright © 2021 DOB Sales - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.