DMC 70

Its high level of versatility makes dmc sd 70 perfect for different types of machining. In the furniture sector (with veneered and painted panels) it excels in the provision of optimum level finishing thanks to the 2.620 mm sanding belt length and the electronic sectional pad.

Advantages

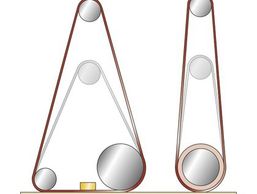

Long belts: 2.620 mm length for greater finishing and productivity

Better cooling of the abrasive grit due to the greater development of the belts that reduces the adherence of processed dust.

An extended belt length lasts longer, requires fewer replacements and consequently less downtime.

Automatic feed belt tensioning and centering: for an easy operation

An electro-pneumatic system keeps the feed belt on track, perfectly centered and tensioned at all times. The system is automatic and no operator intervention is required.

Belt oscillation controlled by an electronic photocell

This precision control system maximum uniformity in belt oscillation: this reduces the risk of belt breakage and improves finishing quality.

DMC sd 90

Maximum performance for companies increasing production. Designed for the medium to high industrial companies that require diversified machining, dmc sd 90 satisfies all calibrating and sanding requirements, by offering a wide range of technological solutions allowing the possibility of customizing the machines compositions. The availability of offering many types of operating units such as planing units, roller units (with 175, 220, 250 and 320 mm diameters), pad units and superfinishing units guarantees the very best results on solid wood, veneer, laquer and paint operations.

Advantages

Superfinishing unit: for sanding at the highest level

Uniform finish with the Chevron belt which improves the cooling of the abrasive action on the work piece, the wide contact surface and the copying capacity of the “MESAR” electronic pad. The unit is particularly suitable for the superfinishing of solid wood components, MDF panels that have been laminated, veneered or painted (opaque and polished).

Integrated electro-fan provides extreme compactness.

Reduced overall dimensions and noise emissions with the device positioned under the work table.

“Mesar” sectional pad: the best finish with any material. Higher quality results due to the special shape of the sectors that allows the operator to intervene “softly” but also in an “aggressive” way, simply by varying the working pressure. The setting of the pad position and the possibility of using foils of different thickness increases its versality.

LOGIC TS control: programming work becomes simple and effective

With LCD display and touch-screen function, it allows the complete and safe control of the machine, easily and intuitively.

The possibility to store up to 120 work programs to retrieve the machine settings most commonly used makes it perfect even for unskilled operators.

Videos

Sandya 900 RCS

Sandya 900 RRT

Sandya 900 RRCS 135 automatic wide belt sander with planer unit

Give customers a reason to do business with you.

SCM DMC 900 cross belt

Contact Us

Call or text Ken Dobranski at 587-888-0818

or email ken@dobsales.com

Copyright © 2021 DOB Sales - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.